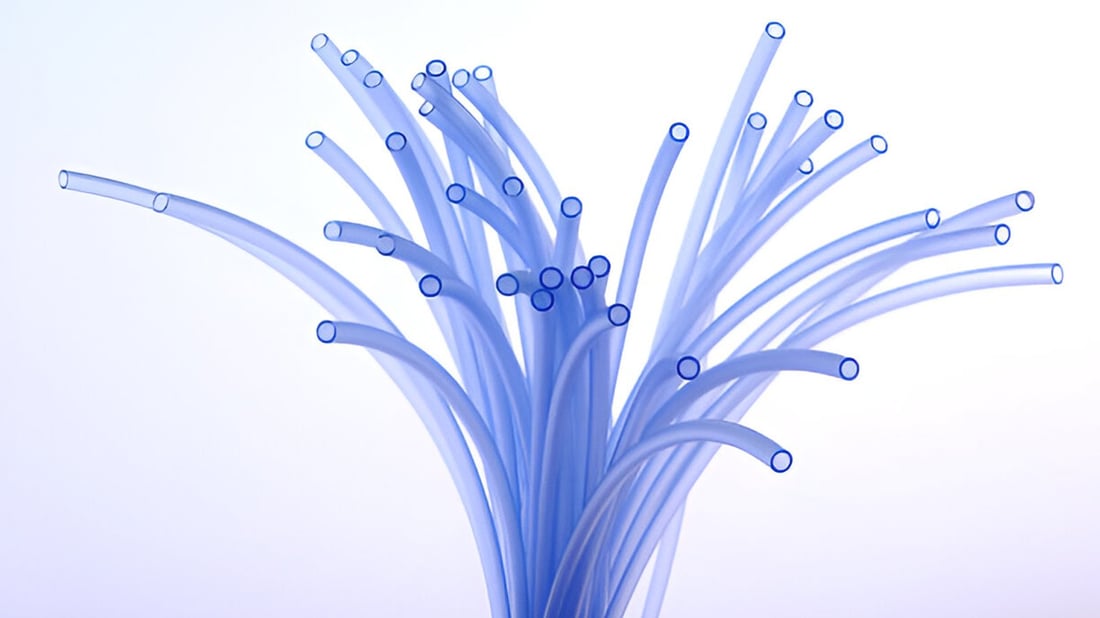

The Versatile Silicone Tube: A Solution for Various Industries

Silicone tubes are widely used in various industries, from automotive to medical, and even in the food industry. This versatile material has great properties that make it useful in diverse applications. This article explains the advantages of silicone tubes and how they can benefit your industry.

High Temperature Resistance for Industrial Applications

Silicone tubes have excellent heat resistance capabilities, which make them perfect for high-temperature industrial applications. These tubes can withstand temperatures between -60°C to 200°C, making them ideal for use in the chemical, pharmaceutical, and power generation industries. They can handle high heat without breaking down or releasing toxic gases, which can pose a danger in some manufacturing processes.

Non-Toxicity for Food and Beverage Industry

The food and beverage industry demands strict health and safety regulations. As silicone tubes do not contain toxic compounds that can leach into food, they are a perfect choice for these applications. They are also easy to clean and sanitize which reduces the risk of contamination in the food processing process.

Flexible and Resilient for Medical Industry

Medical devices and equipment require flexibility and resilience to work correctly. Silicone tubes have the capability to flex without breaking, making them perfect for various medical applications. They are also soft and compatible with the human body, making them perfect for use in drug delivery systems, catheters, and other medical devices.

Durability for Aerospace Industry

Aerospace companies require materials that withstand extreme temperatures, harsh chemicals, and pressure changes in flight. Silicone tubes are known for their durability and ability to withstand long-term exposure to high temperatures, UV radiation, and harsh chemicals. They are also lightweight, making them an ideal material for aerospace applications.

Tensile Strength for Industrial Uses

Silicone tubes have a high tensile strength, making them useful for various industrial uses. They can be used as seals and gaskets, cable insulation, and in automobiles to transfer fluids. Also, they can withstand pressure changes making them perfect for use in hydraulic and pneumatic systems. They also maintain their strength even at high elongations making them ideal for applications that require high flexibility.

Chemical Resistance for the Chemical Industry

Silicone tubes have excellent resistance to chemicals, offering high performance in harsh chemical environments. These tubes offer high resistance to acids, bases, solvents, fuels, and oils. This property makes them ideal for handling chemicals in laboratories, agriculture, and petrochemical industries.

Low Compression Set for Durable Sealing

Silicone tubes are known for their lower compression set compared to other rubber materials. A compression set is a measurement of how much the material will maintain its original shape after being compressed. The lower the compression set, the better the sealing capabilities. This property makes silicone tubes suitable for applications that require long-lasting and durable sealing such as in automotive and home appliances.

Electrically Insulating for Electronics Industry

Due to their excellent electrical insulating properties, silicone tubes are ideal for use in the electronics industry. They have high dielectric strength, making them perfect for insulation in electrical connectors, cables, and circuit boards. Also, they have good thermal conductivity and resistivity, making them ideal for use in power applications.

UV Resistant for Outdoor Uses

Silicone tubes are resistant to UV radiation and offer good weathering properties, making them suitable for outdoor uses. For example, in solar, marine, and outdoor lighting applications, they can withstand a range of temperatures, humidity, and exposure to sunlight without degrading. Silicone tubes can also maintain their properties after years of exposure to the weather, which reduces the need for frequent repair or replacement.

Easy to Fabricate for Custom Applications

Silicone tubes are easy to fabricate which makes them ideal for custom applications. They can easily be cut, shaped, and extruded into various shapes, sizes, and formulations. This property allows manufacturers to create unique and custom products that meet their specific requirements.